Direct Hot Air Generators

Used for heat transfer for industrial purposes.

The direct type generators with combustion fumes mixed with the process air, equipped with burners, running on gas, liquid or solids fuels. Electrical or hybrid systems can also be supplied.

Main industries of use: ceramic, bricks, minerals, detergents etc.

They can be of two categories depending on the type of burner. When the burner is of the air duct type we construct the generator as a complete crossing, that is the process air and the combustion fumes are mixed directly in the combustion chamber. The construction can include internal or alternatively external coating.

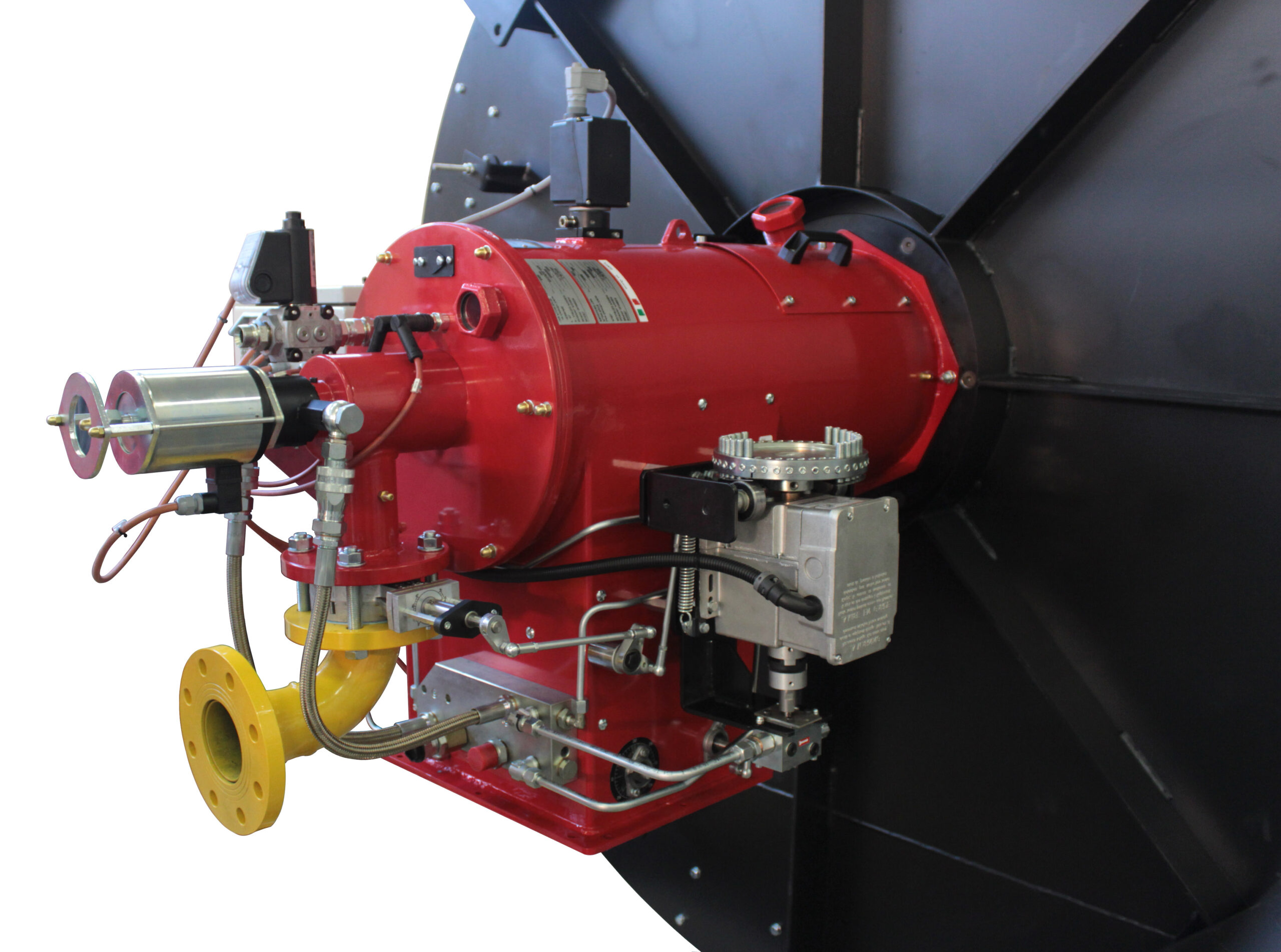

When the burner is of the traditional type we construct a generator that provides a concentric external structure with the combustion chamber. Generally the construction requires internal coating in refractory material where the burner flame can develop.

Between the external structure of the generator and the interior combustion chamber we have a space for the passage of process air. The process air also has the function of “cooling” the combustion chamber both internally and externally.

At the end of the generator the combustion fumes and process air are mixed together.

These can be designed either in horizontal or vertical axis.

Indirect Hot Air Generators

Generators of the indirect type which separates the combustion fumes and process air, equipped with burners that run on gas or liquid fuels.

Main industries used: Food and cereal drying

Technical features

Electrically powered generators

Product Details

The electric generators are designed according to the needs of the customers and the systems in which they are to be installed.

The heat generator is made with a process channel section in which the electric resistors and junction boxes for wiring are housed; the supply is completed with the electric control panel.

The management of the generator is made to have the widest range of modulation, even 0-100 %.

The management of the temperature and the resistors of the generator itself, can be made with PLC.